High quality tools

for industry

G25 is 25 years of experience, so that the future belongs to you

Over 25 years of

experience

G25 products are carefully selected tools that are produced for us by the highest standards of domestic and foreign companies. The choice was made based on our commercial and production experience and on the technical opinions of trusted users, in terms of the needs of our customers.

Our achievements

We have worked for the G25 brand for over 25 years.

Hundreds of suppliers, thousands of brand products in the portfolio. Hundreds of employee trainings, thousands of kilometers traveled. Favorite, difficult and unassailable customers.

We combine these experiences and knowledge with a flexible approach to the client and building relationships.

Together with our clients, we want to think about the future.

Our ambition is to infect small and medium-sized production companies with the idea of optimization and automation.

25

Years of experience

180

Employees

23

Branches throughout Poland

25+

Years of experience in industry and commerce

7

Years of building the G25 joint project

Over 25 years of experience

G25 means over 25 years of experience in servicing industry in Poland and over 25 years of gaining know-how in trade in the tool industry. We have worked for the G25 brand for over 25 years.

The highest quality and standards of products

G25 products are carefully selected tools that are produced for us by the highest standards of domestic and foreign companies. In the era of Industry 4.0, products alone are not enough - we also offer our clients a tool management system that optimizes and automates the process of using tools in production.

Local, partnership-based relationships

Operating in various regions of Poland, we build local, partner relations with clients, ensuring the highest quality standards for tools and service.

Contact

Write to us

Designed by SEO partner

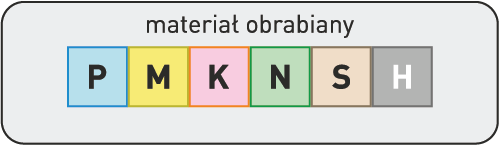

Legend

1. Worked material

ISO P & #8211; steel

ISO N & #8211; non-ferrous metals

ISO S & #8211; heat resistant super alloys

recommended

ISO K & #8211; cast iron

ISO H & #8211; hardened steel

ISO M & #8211; stainless steels

admissible

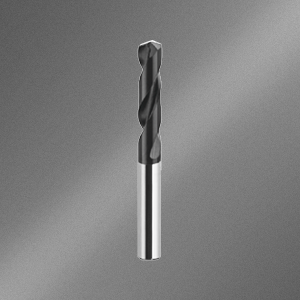

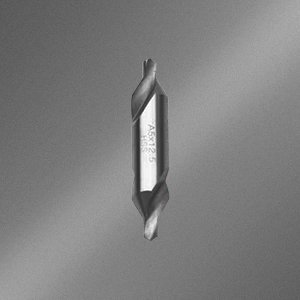

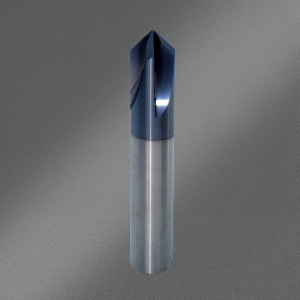

2. Material of the cutting part

high speed powder steel with cobalt content

high speed steel with cobalt content

standard high speed steel

high speed steel with cobalt content

solid carbide tools

high speed steel ground

3. ISO standard

HA straight cylindrical shank

HA straight cylindrical shank

twist drill with cylindrical shank

twist drill with Morse taper & #8217; a

tool made according to DIN 374

tool made according to DIN 376

tool made according to DIN 333

tool made according to DIN 374

tool made according to DIN 376

tool made according to DIN 333

4. Coatings

TiALN + Tin

TiALN + WC / C

aluminum titanium nitride

titanium nitride

oxidised coating

TiN + TiCN

AlTiN

covered

uncoated

5. Additional markings

twist drill

cylindrical handle

Morse taper & #8217; a

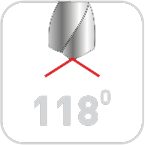

blade angle

range of helix angle

helix angle

internal cooling

working part length

countersinking angle

number of cutting blades

number of cutting blades

type N & #8211; cutting materials with normal strength and hardness

If something seems incomprehensible please contact us.